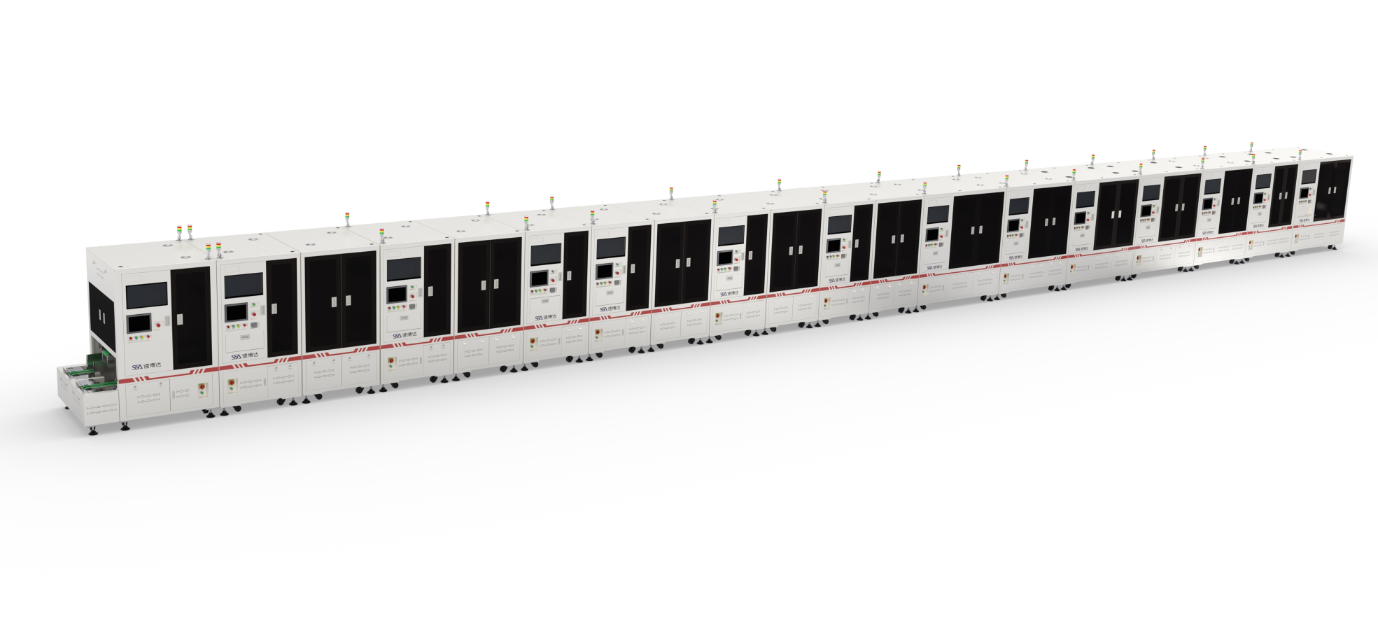

High speed flexible production line for mobile digital single cell batteries

PCBA assembly line

High speed flexible production line for mobile digital single cell batteries

PCBA assembly line

This automated production line can fully automatically complete the core feeding, OCV testing and lug cutting, packaging top sealing adhesive and silicone pad, PCM board feeding and laser welding, solder joint detection and PCM bending, packaging PCM board adhesive, FPC bending and packaging peripheral adhesive, packaging bottom adhesive, packaging lifting hand glue, VOC leak detection, easy to tear paste, Double-sided tape paste and pressing, size measurement, function test, terminal appearance detection and size measurement Finished product cutting and other battery pack production processes.

The entire line adopts a single machine modular design, which can increase or decrease processes and equipment according to actual needs to achieve human-machine integration.

External dimensions

24000mm * 1200mm * 1900mm

Direct rate

98%

Conveying method

Front section: Vehicle conveying Rear section: Belt+robotic arm

Noise

≤ 70db

Working voltage

220V

Equipment power

60KW

Capacity

1200 PCS/H

Final yield

99.5%

Data upload

Supports binding with MES

Temperature

0-45 ℃

Working air pressure

0.5-0.7Mpa

Production manpower

7 people