Home Storage Pack Expressway

PCBA assembly line

Home Storage Pack Expressway

PCBA assembly line

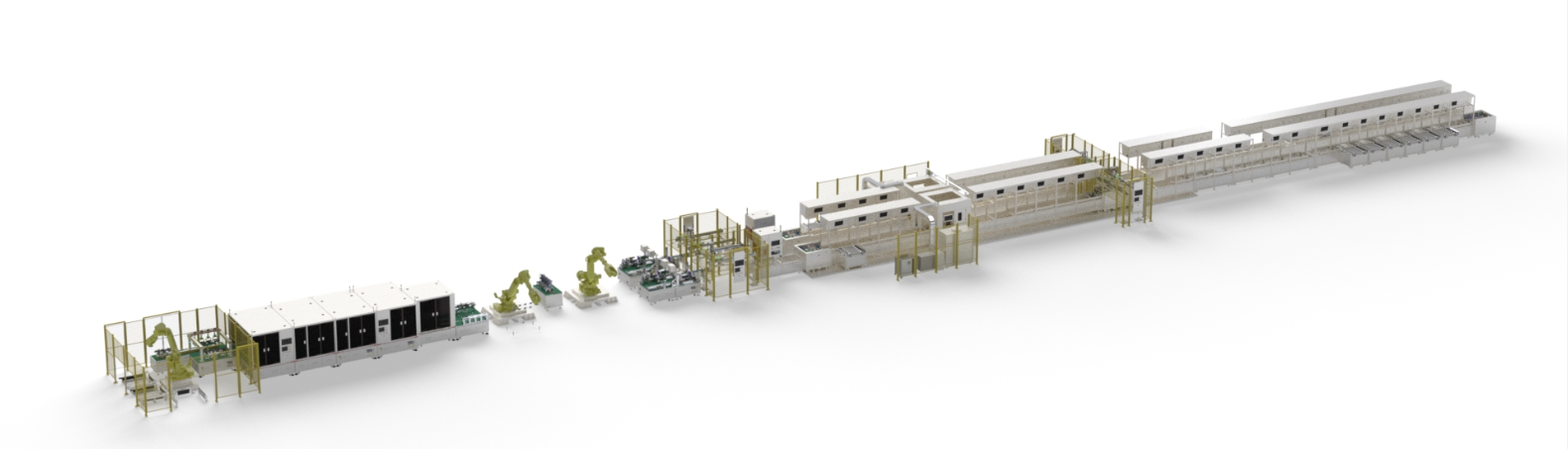

This automated production line serves Time Tech and is used for the integrated assembly production of home appliance energy storage battery packs. Its processes include: appearance inspection of battery cells, automatic feeding, OCV testing and sorting, automatic gluing, module stacking and assembly, polarity testing, insulation testing, pole addressing, CCS installation, Busbar welding, EOL testing, full size testing, module packaging, module fixation, wire harness connection, performance communication testing, pack offline Product aging, product packaging, etc. Upload production line data to MES, complete product production process data upload and traceability.

External dimensions

86000mm * 16000mm * 3200mm

OEE

85%

Conveying method

belt+double speed chain/drum

Noise

≤ 75db

Working voltage

380V

Equipment power

325KW

Capacity

120 modules/h

Final yield

99.9%

Data upload

Supports binding with MES

Temperature

20-35 ℃

Working air pressure

0.5-0.7Mpa

Production manpower

38 people