Power Pack Line

PCBA assembly line

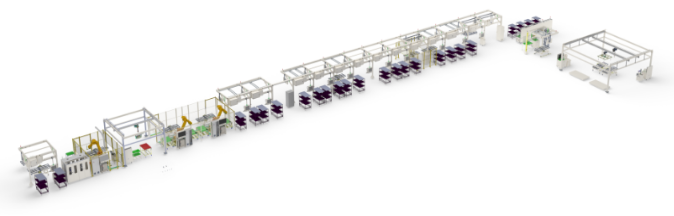

Power Pack Line

PCBA assembly line

This line is used for pack assembly production of BEV battery products. The PACK main line includes cleaning the lower box, installing inlet and outlet water pipes, automatic gluing of the box, manual insertion of reserved modules, automatic insertion of modules, module fixation, installation of BMS, installation of BDU and external plugins, wiring harness connection, high pressure copper bar connection, quality inspection, wiring harness fixation, wiring harness organization, liquid cooled plate airtightness test, safety testing, installation of explosion-proof valves and sealing rings Fixed sealing cover, box airtightness test, EOL test, capacity test, PACK weighing offline and other processes.

External dimensions

70m * 8.6m * 3.5m

Direct rate

≥ 99%

Conveying method

AGV+tooling truck

Noise

≤ 75db

Working air pressure

0.5-0.7Mpa

Production manpower

17 manual stations and 3 automatic stations

Capacity

min/pack

Final yield

≥ 99.8%

Data Upload

MES

Working voltage

220V

Equipment power

100KW

Overall size

16 people