CTP automatic line

PCBA assembly line

CTP automatic line

PCBA assembly line

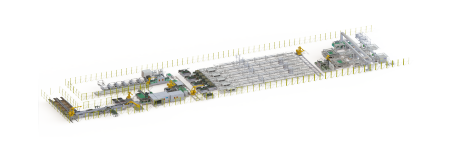

The current production system adopts three parallel production lines of the same production line, with a single independent production capacity of 4 minutes/Pack. The conveyor line is combined with AGV production, and the adhesive curing is accelerated using a tunnel furnace method.

The single line production covers an area of 200 meters x 15 meters x 3.8 meters with a clear height. 15 6-axis robots and 45 intelligent AGVs are used in the production of the single line.

Cell production section: The production speed of cell online and cell function processing can reach 2s/pcs=30ppm/min. On average, the battery cells are replenished every 2 hour cycle.

Pack production section: Pack production adopts AGV mode for flexible transportation, and the central cluster control scheduling system for flexible scheduling of production.

Cell parameters

117A/H Cell 98 Cell/Pack package

Finished Pack Weight

265 kg

Pack Dimensions

L=1500 W=1100 H=280